Real-time monitoring involves the continuous collection and inspection of data from heating systems equipped with embedded sensors, controllers, and network-enabled interfaces. Rather than periodic manual inspections, engineers and operators are able to view live information on:

These digital heating systems employ thermocouples, PID controllers, and industrial IoT gateways to send data back to a central dashboard, where trends, anomalies, and alerts can be monitored immediately, even remotely.

For example, a plastic packaging plant employing DHE’s band heaters with built-in thermocouples cut abrupt heater failures by 40% after adopting real-time temperature monitoring and threshold-based alerts.

The move to smart heating isn’t a fad; it’s a requirement. Industrial processes are under continuous pressure to:

Legacy heaters work in a siloed manner. If a breakdown occurs, the system can operate undetected until product quality suffers or equipment halts. With digital heat solutions, issues are flagged early, and processes become proactive rather than reactive.

At DHE, we think heating systems are not passive equipment, but smart assets that provide quantifiable value to the operation.

Real-time data allows teams to detect abnormal behavior in resistance, temperature, or power draw, usually early indicators of heater breakdown or failure. This enables operators to act before a failure happens.

A food processing firm employing sensor-enabled cartridge heaters experienced steady thermal lag during startup. The analytics solution indicated the shift, which prompted a preventive replacement. This prevented a production halt and saved almost ₹5 lakhs in avoidable losses.

In applications such as injection molding or chemical dosing, thermal stability is unavoidable. The slightest change in temperature affects material flow, cure speed, or product consistency.

Computer-controlled heating systems continually adjust to keep within tight tolerances without the overshooting or lag that is prevalent in older systems.

Zone-level control, dynamic power adjustment, and detection of idle heating are made possible with real-time monitoring. Rather than turning on all the heaters at maximum capacity, the system optimizes heat delivery according to process demand.

Heating, as per the U.S. Department of Energy, contributes between 20% to 30% to industrial energy consumption. Maxing this out with real-time controls can result in annual energy savings of 20–35%.

Advanced heating solutions with built-in monitoring identify overheating, electrical imbalance, and grounding faults in real time. This provides conformity with safety requirements (OSHA, IEC, RoHS) and environmental regulations with protection for personnel and equipment too.

Historical logs of data also make audits easier, providing unambiguous evidence of temperature patterns and system integrity.

When sensor measurements are logged over time, long-term trends like thermal drift, resistance decay, or inefficiencies associated with startup or shutdown processes are made visible.

With the addition of historical analysis to real-time monitoring, plant managers receive rich operating insights that guide maintenance schedules, equipment upgrades, and process optimization.

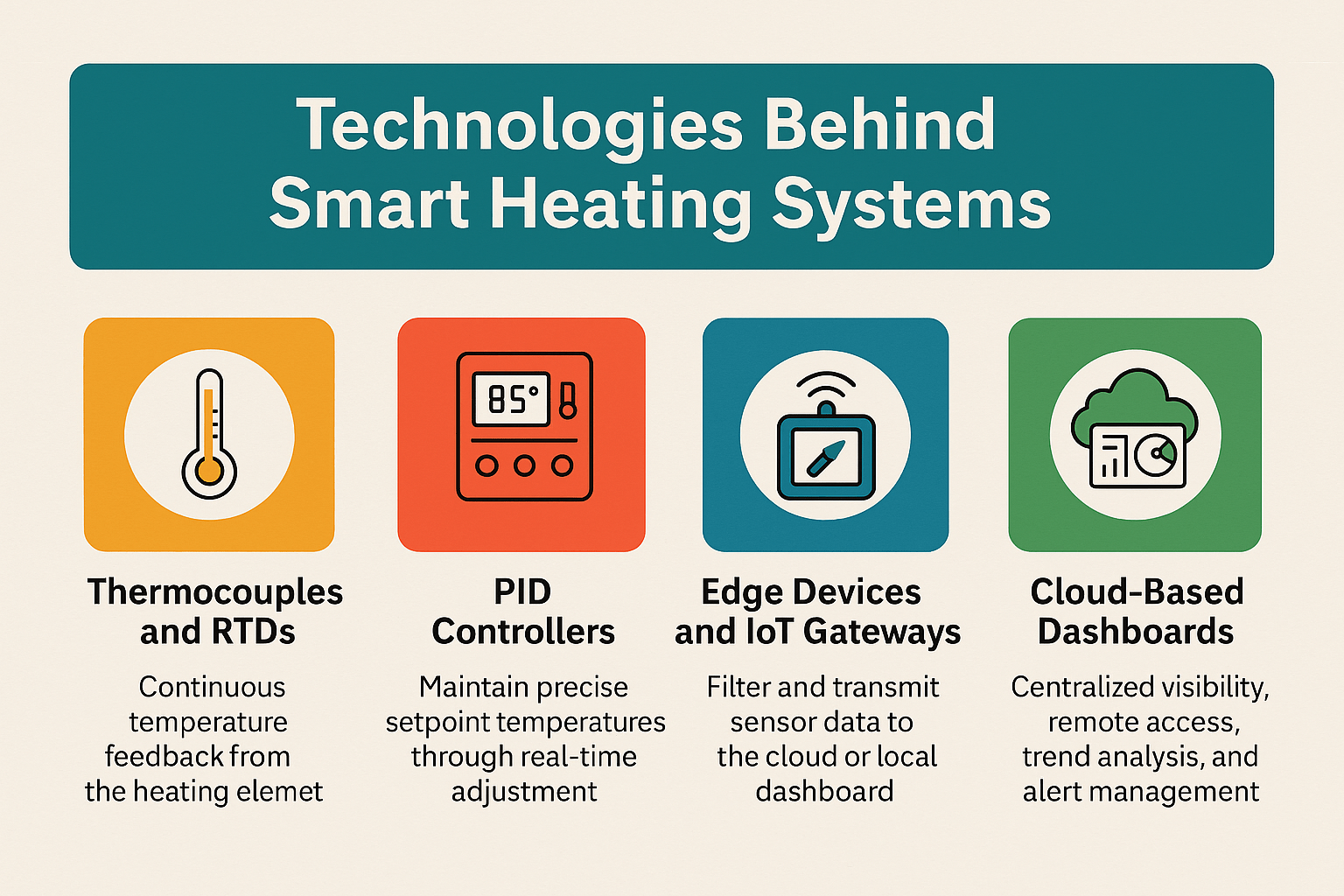

The transition to smart thermal control depends on a variety of interrelated technologies:

DHE’s heating solutions support Modbus, OPC UA, and other industrial protocols, making integration with your existing automation stack frictionless. Our industry-leading heating solutions have helped save industries millions on manufacturing costs!

Get in touch with us today to learn how DHE can optimize your heating processes and reduce your bottom line.

Digital transformation doesn’t mean replacing your entire system overnight. A phased, strategic approach ensures success:

As industrial processes become more advanced, heating systems will become increasingly autonomous and intelligent. Here’s what the future holds:

Early adopters will enjoy operational flexibility, energy resilience, and an enhanced compliance advantage.

Let’s remember that Heating with Intelligence Is No Longer Optional.

Competing in today’s industrial landscape requires embracing the technology of reduced waste, increased uptime, and smart decision support. Heating systems must move beyond the static, energy-draining tools of the past to dynamic, intelligent parts of your operation strategy.

DHE Heaters is dedicated to fueling that evolution. With a lineup of sensor-enabled heaters, customizable digital controls, and industrial-strength monitoring systems, we assist innovative manufacturers in eliminating the guesswork from heat and deploying data to work.

Survey No. 687/1, Hirapur Cross Road, Mahemdavad Highway, Hirapur-Barejadi Road, Ahmedabad – 382435