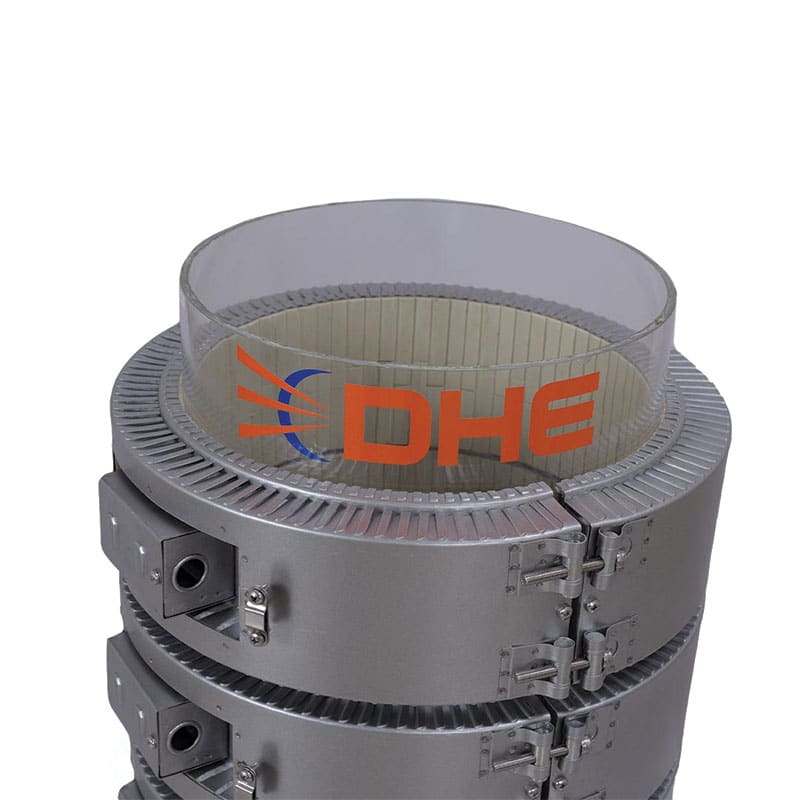

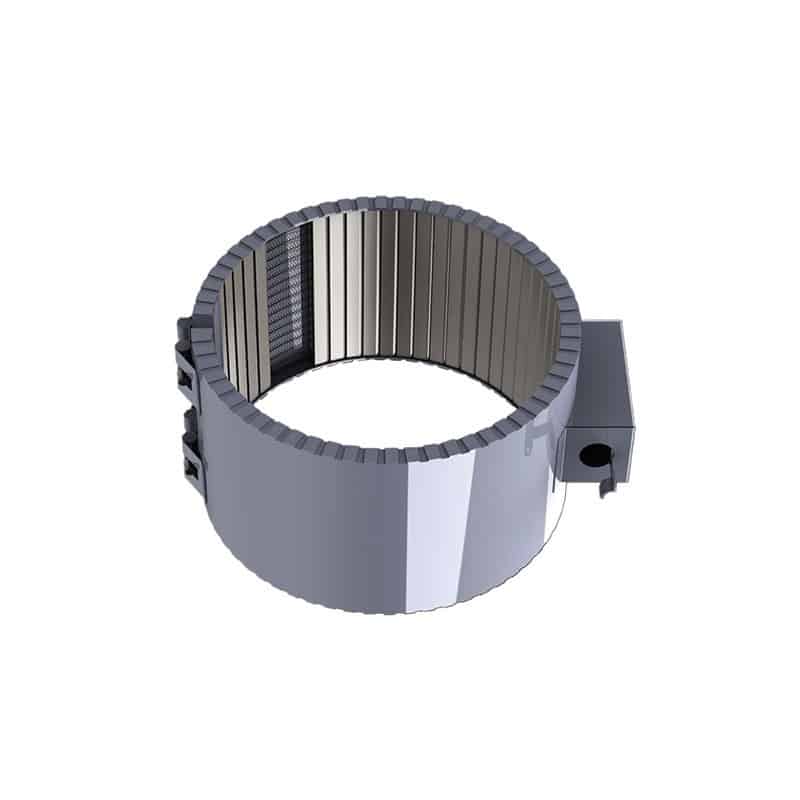

DHE Offer ceramic band heaters are designed to meet industrial needs for high temperature, durable heaters. These heaters are well-suited to meet the demands of today’s new resins, where process temperatures are constantly increasing. This ceramic band heater has spirally wound internal resistance coils that are threaded through interlocking ceramic “tiles”. The ceramic core or “mat” of the tiles is hidden under a stainless steel sheet that has serrated edges. The combination of the two makes this heating system flexible and efficient. The heat in the ceramic band comes from the inner coils, which conduct heat at the highest temperatures. They evenly distribute heat through the tiles, which then radiate energy into the barrel. We have a bunch of different ceramic band styles with different configurations.

Ceramic Band Heater Power Saver

DHE also offers ceramic band heaters that are specially developed for injection molding machines and where higher temperatures are required. These heaters can save up to 30% of power. Outer shell temperature will be 70°C at a time of 250°C Temperature measured on the barrel. The element winding is designed to heat the ceramic blocks to the point at which they radiate energy into the barrel as well as conduct energy by being in contact with the barrel.

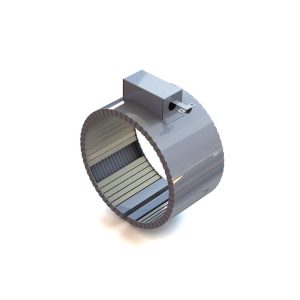

Perforated Ceramic Band Heater

We also offer perforated ceramic band heaters, which are widely used for PVC injection molding, cooling on extrusion, and blow molding machines. The heater band is 60% open by perforated metal sheet, which ensures maximum surface exposure for better cooling. The heater band is covered with a blower cover for mounting the blower. Advantages of air-cooled over liquid-cooled operations include lower cost, easy replacement, low maintenance, no leakage problems, and uniform temperature control.