Step into any manufacturing floor, and the enormous machines, the conveyor belts, the whir of production immediately catch your eye. But what about the little pieces? The ones that operate with quiet efficiency to keep everything clicking?

If your company operates with plastics, extrusion, food processing, or chemicals, you already depend on one of these unsung heroes: the mica band heater.

It’s not glamorous. It’s not boisterous. But without it? Production falters. Quality decreases. Energy bills rise.

Here’s the reality. Selecting the finest mica band heater in the industry is not simply purchasing an element. It’s about safeguarding your product, managing your expenses, and minimizing downtime. It’s investing in quality, cost control, and uninterrupted production.

Upgrade to DHE’s industry-leading mica band heater and optimise your process today.

Imagine a heat belt for the barrel on your machine — close, accurate, and consistent.

A mica band heater consists of:

Imagine this: Power travels through the resistance wire.

The wire heats up quickly.

Mica insulation distributes that heat evenly into the sheath.

The sheath transfers it directly into your barrel, nozzle, or pipe.

Simple, right? But here’s the catch: a poor-quality heater will waste energy, create hot spots, or fail early.

And who wants to gamble with production like that?

So here’s how the Best Mica Band Heater in the Industry is a Game-Changer

1. Cuts Energy Costs

Tight barrel contact means less heat escapes into thin air. Why pay for energy you’re not even using?

2. Always Keeps Quality on Target

Uniform heat = uniform product. No more surprises when you inspect the batch output.

3. Longer Life

Our heaters don’t quit on you too soon. You get more life, fewer replacements, and more uptime.

4. Operates Across Industries

Melting chocolate or processing polypropylene, this heater’s got your back.

View all our Industrial Heaters.

It’s easy to build a heater. But one that lasts year after year? That takes know-how.

At DHE, each mica band heater is:

Let’s face it — there’s no single solution.

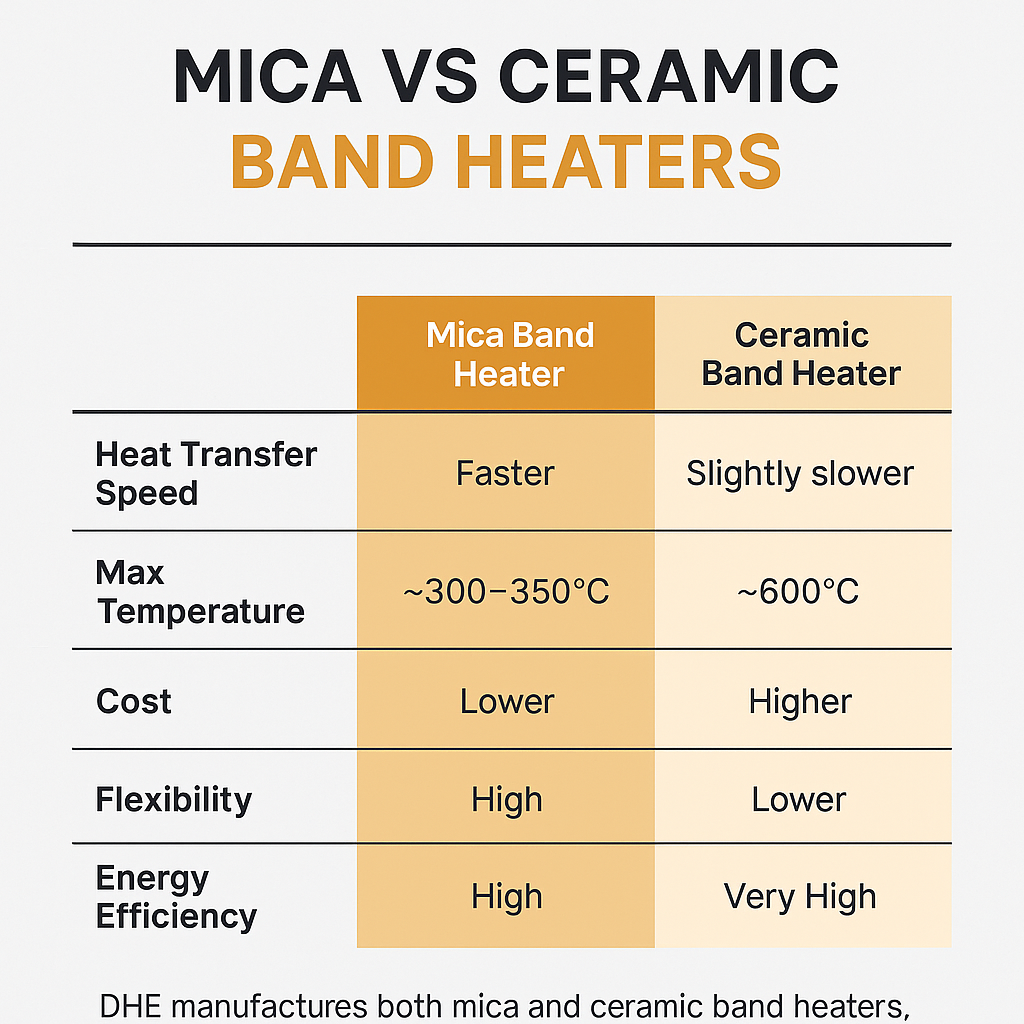

Here’s the shorthand rule: Under 350°C, mica is most likely going to be faster and cheaper. Over that, ceramic could be your champion and yes, DHE produces both.

One of our automotive production customers was losing money and time to hot-and-cold heating. Their parts were warping out, and their reject bin was growing.

We replaced them with DHE mica band heaters featuring integral thermocouples. Within 90 days:

Don’t you want results like that?

Before you order, ask yourself:

Not certain of the responses? That’s okay — we walk customers through this daily. Get in touch with us through our Contact Page.

Because we don’t merely sell heaters, we design solutions.

If you are already using a mica band heater for industrial use, here are a few easy-to-follow tips that will keep your industrial mica band heater running like new! amp it firmly — no air space.

2–3 years of continuous operation, with good care.

Yes, if you opt for the stainless steel-sheathed type.

If you operate below 350°C, yes — and you may end up saving money as well.

A leading quality mica band heater for your factory use may not be the largest purchase on your factory floor, but it’s one of the best. Select the top mica band heater in industries from DHE Industrial Heaters, and you’re selecting performance, dependability, and reduced expenses. After all, isn’t that what every manufacturer desires?

Get a quote for your Mica Band Heater today.

Survey No. 687/1, Hirapur Cross Road, Mahemdavad Highway, Hirapur-Barejadi Road, Ahmedabad – 382435