When it comes to the plastics and automobile components industry, time is money. A couple of seconds in an injection moulding heater cycle or a minor spike in barrel temperature can translate to thousands of spoiled parts and hours of lost production. That’s precisely the problem that a Tier-1 automotive parts supplier in India was facing. This was before their approach to DHE Heaters, a reputed industrial heater manufacturer in India, which offered them the best industrial heating element, which in turn helped them turn their business around.

Here’s a peek into behind the scenes of how DHE, the best cartridge heater supplier and band heater with thermocouple expert, collaborated with the client to redesign their heating system.

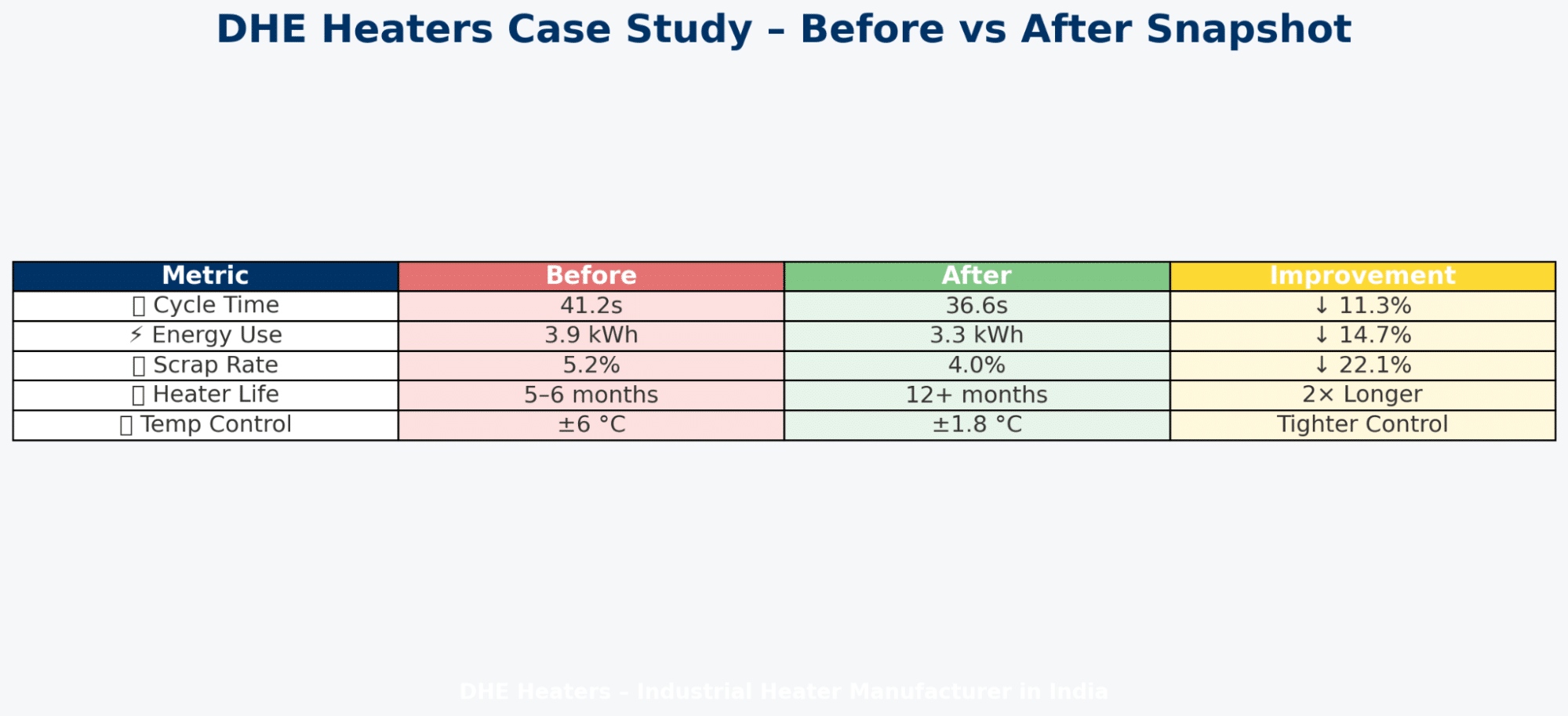

The outcome was difficult to ignore! Cycle times reduced by over 11%, energy consumption decreased by nearly 15%, scrap decreased by 22%, and heater life doubled.

If you are seeking similar problems and need optimal results, Speak to a DHE Engineer Today

They required more than replacement parts. They required an India-based partner-level industrial heater company that could audit, design, and provide customized injection molding heaters for long-term impact.

The best industries are saving with DHE’s leading industry heaters, and we wanted to extend this benefit to the problem at hand here as well. So here’s what we did.

Step 1: Thermal Audit

Step 2: High-Density Cartridge Heaters

Step 3: Band Heaters with Thermocouples

View our Band Heaters with Thermocouples for industrial heating.

Step 4: Control Optimization

Step 5: Floor-Specific Customizations

For the ideal Custom Heating Solutions, get in touch with us today!

“Rejection rates decreased. Energy savings were evident from month two. ROI was a no-brainer.” – R.K., Production Head

This is why manufacturers in plastics, packaging, and the automotive industry regard DHE as the premier industrial heater manufacturer in India.

The story of this auto parts supplier is evidence that when you select an industrial heater producer in India who behaves like a partner rather than simply a parts supplier, you gain genuine ROI. With cartridge heaters with high-density band heaters, with thermocouples and custom injection molding heaters, DHE Heaters saved scrap, reduced energy, and increased heater life.

Stop wasting energy. Start saving money. Talk to a DHE Engineer and transform inefficiency into measurable gains.

Survey No. 687/1, Hirapur Cross Road, Mahemdavad Highway, Hirapur-Barejadi Road, Ahmedabad – 382435