At DHE Heaters, we do more than sell products. We provide solutions.

Being one of India’s best industrial heater manufacturers, we were approached by a well-known chemical plant with vital heating inefficiency issues. By combining our customized solution and expertise in creating the best industrial heaters in the market, we assisted the customer with temperature accuracy, energy efficiency, and continuous production.

A major Gujarat chemical processing facility faced production losses and increased operating expenses. Their solvent evaporation unit, which plays a pivotal role in product blending, experienced inconsistent heating. The problems arose from aging heaters that were not highly controlled and could not effectively maintain temperature consistency in batches.

Pain Points:

Even after several rounds of maintenance and hardware replacement, the issue remained unresolved, impacting both productivity and process stability. It became clear that incremental fixes were no longer enough, and a smarter, future-ready heating system was needed.

One of the client’s senior technicians shared, “We’ve tried multiple repairs, but the problems just kept coming back.”

With industrial heating technology evolving rapidly, staying updated on the latest innovations can make all the difference. That’s why we’ve highlighted key developments in our blog: 5 Industrial Heater Trends That Are Revolutionizing the Industry.

With a focus on being one of the most reliable industrial heater suppliers in India, DHE Heaters tackled the challenge with a consultative approach. We began with an in-depth process analysis at the customer’s site, considering operational parameters, heating medium compatibility, material exposure, and available controls.

Our on-site engineers immediately noted critical points that others had overlooked.

Critical Observations:

Our engineers suggested a custom tubular immersion heater system with digital control capabilities from this analysis.

DHE developed and supplied a completely bespoke immersion heater solution, specifically designed to the client’s requirements:

Key Features:

We worked closely with the client to ensure minimal downtime during the upgrade. To know more about our diverse range of top industrial heaters in India, you can go through our product catalogue.

The Outcome: Superior Results

In the first 60 days of deployment, the client achieved quantifiable gains:

Results:

After implementing DHE’s custom tubular immersion heater system, the chemical plant began seeing measurable improvements—not just in heating consistency, but across their operations and bottom line.

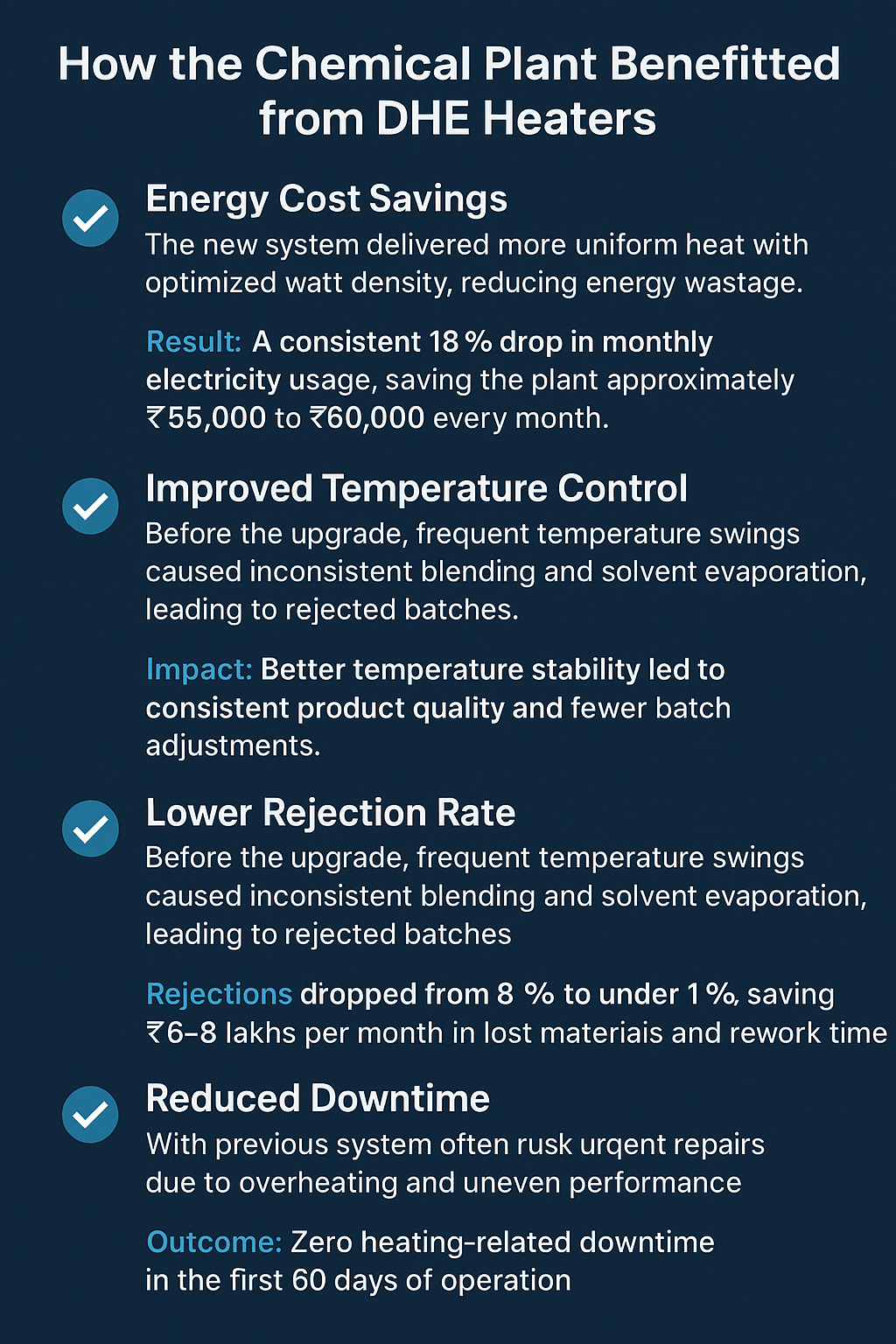

The new system delivered more uniform heat with optimized watt density, reducing energy wastage.

Result: A consistent 18% drop in monthly electricity usage, saving the plant approximately ₹55,000 to ₹60,000 every month.

With PID controllers and precise thermal calibration, the heating process maintained a deviation of just ±1°C.

Impact: Better temperature stability led to consistent product quality and fewer batch adjustments.

Before the upgrade, frequent temperature swings caused inconsistent blending and solvent evaporation, leading to rejected batches.

After Installation: Rejections dropped from 8% to under 1%, saving ₹6–8 lakhs per month in lost materials and rework time.

The previous system often needed urgent repairs due to overheating and uneven performance. DHE’s system, with safety controls and robust materials, operated seamlessly.

Outcome: Zero heating-related downtime in the first 60 days of operation.

With stable performance and fewer disruptions, the plant could complete more batches during regular shifts.

Boost: A 12% increase in monthly output, achieved without adding work hours or additional staff.

“DHE Heaters provided us with exactly what we required—a reliable, power-efficient system that integrates well with our controls. It has revolutionized our production line.” — Head of Operations, Chemical Manufacturing Company

We’re an established brand among top industrial heater manufacturers in India due to our dedication to quality, engineering know-how, and customer focus.

Our Strengths:

A1: We use high-quality materials and custom designs tailored to your process, ensuring durable and long-lasting heaters.

A2: We offer full installation help, maintenance advice, and quick troubleshooting for seamless operation.

A3: Yes, our solutions include PLC integration for smooth real-time process control.

A4: Our heaters feature digital PID controllers and optimized watt density to minimize energy consumption without compromising performance.

Heating might be just one part of your industrial process, but when it fails, everything suffers. With DHE Heaters as your partner, you get more than just a product. You get a solution tailored for reliability, precision, and long-term performance.

If you’re looking for the best industrial heater in India, connect with us to find a solution that fits your application and delivers measurable results.

Survey No. 687/1, Hirapur Cross Road, Mahemdavad Highway, Hirapur-Barejadi Road, Ahmedabad – 382435