Walk through any modern factory. A plastics molding unit, a pharma packaging line, or a shiny new EV assembly line, and you’ll see robotics, sensors, and high-precision machines. But behind the visible technology are heaters, often overlooked but absolutely vital.

Heaters decide if production is smooth or comes to a stop. Being a little off-mark can result in tough plastics, opened packets, or lost batches. That’s why leading ceramic manufacturers in India are creating the best engineered products. Ceramic heaters are gaining acceptance as the workhorse of industrial heating. And more and more, the firms making these heaters are forging the future of industries. The leaders mentioned are ceramic heater manufacturers in India and how these industries heat, conserve energy, and remain competitive.

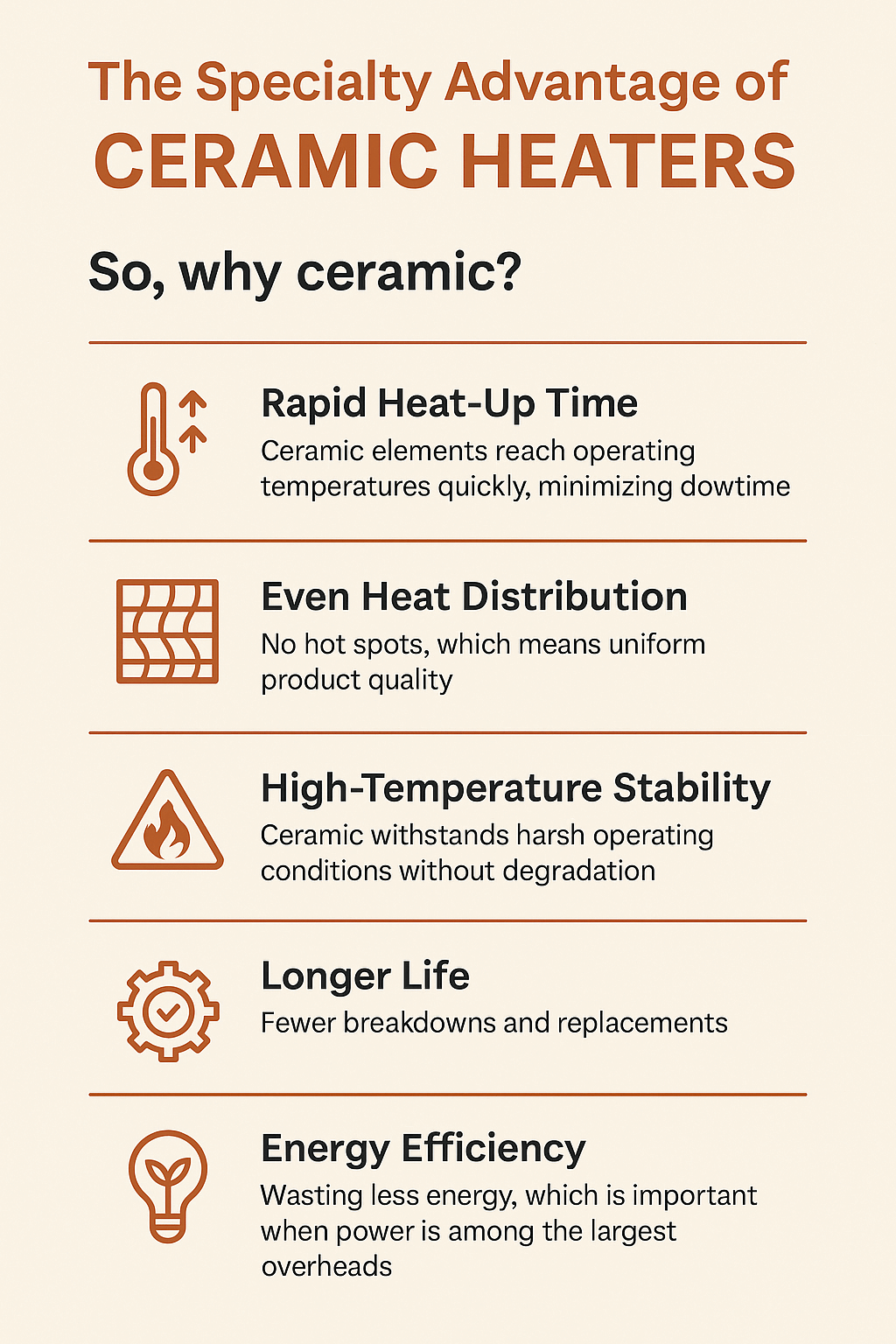

So, why ceramic?

Ceramic heaters do more than simply generate heat, unlike traditional heaters:

And that’s why companies are increasingly turning to ceramic as their go-to solution for heating. Leading manufacturers of heating components in India, such as DHE have emerged as trusted ceramic heater manufacturers in India, delivering energy-efficient, durable, and customized solutions for industries worldwide.

Ten years ago, Europe or East Asia were where global buyers went for heater sourcing. Now, India is part of the mix, and with good reason.

Each factory floor varies. A pharma firm’s heater requirements are not at all similar to a plastics extrusion line. Indian vendors live on customization as opposed to the cookie-cutter approach.

Indian heaters are not bargain-basement prices, but they provide consistent quality at reasonable prices — the right mix international buyers seek.

From ISO 9001 to CE and RoHS, Indian heater manufacturers now conform to the international standards that previously distinguished them from the rest.

Programs such as Make in India and access to export incentives have enabled local players to ramp up, invest in R&D, and compete internationally.

The statistics reveal the tale. The worldwide industrial heating market is set to reach USD 12 billion in 2032. The heater market in India itself is currently valued at USD 100 million and is increasing consistently.

Growth is being fueled by:

Businesses desire heaters that can “speak” — temperature-monitoring sensors in real-time, pre-failure alerts, and minimize unexpected downtime.

Battery packaging and ultralightweight composite plastics demand total precision in heating. Ceramic heaters are on the rise as the supply chain choice for EV.

Energy-saving heating is no longer a luxury. For companies disclosing ESG performance, ceramic heaters contribute directly to carbon emission targets.

With stable supply chains, India is no longer importing technology; it’s now exporting proven industrial heat solutions.

Take a 24/7 injection molding mid-sized plastics maker based in Gujarat. Several years ago, the firm was plagued by:

Then, after upgrading to the best ceramic band heaters from DHE, they described:

Increased temperature consistency, results in fewer batches being rejected.

This practical change is why manufacturers view ceramic heaters as cost-saving investments, rather than as expenses.

Booming hand-in-hand industries like EVs and advanced composites require continued R&D.

But the distinction here is this: companies that are making investments in innovation, client engagement, and IoT-capable designs are setting themselves up to be leaders, not followers.

Here at DHE Heaters, India’s leading manufacturer or industrial heating components, we don’t view ceramic heaters as “spares.” We handle them as mission-critical equipment.

Our ceramic band heaters are designed for:

One of our clients from the packaging industry summed it up best:

“Each hour of downtime costs us lakhs. With DHE heaters, the fear of mid-shift breakdowns just vanished.”

That’s why manufacturers in plastics, food processing, and pharma industries choose DHE , not only for heaters, but also for heating solutions that protect productivity.

As industrial heating engineer Rajesh Patel says:

“Factories no longer ask, ‘How much does the heater cost?’ They’re asking, ‘How much downtime will this heater save me?’ That’s a basic mindset change fueling ceramic heater adoption.”

Anticipate every heater to be equipped with sensors and remote monitoring as standard.

Energy efficiency will have direct correlations with ESG reporting and green certifications.

EV and hi-tech plastics sectors will keep driving demand for precision heaters.

India, with competitive quality and reliability, will keep challenging conventional heater centers.

Ceramic heaters don’t grab newspaper headlines, but they’re the unseen backbone of contemporary industry. They guarantee quality, maintain costs under control, and assist companies in fulfilling their sustainability objectives.

And today, Indian ceramic heater manufacturers are showing they can do better, faster, and wiser.

For companies that seek more than mere equipment, for those seeking trust and approach, there is a clear answer:

Discover DHE’s ceramic heater solutions now. Engineered for performance. Designed for the future.

Survey No. 687/1, Hirapur Cross Road, Mahemdavad Highway, Hirapur-Barejadi Road, Ahmedabad – 382435